RoM BALL MILLS A COMPARISON WITH AG/SAG MILLING

RoM Ball mills – a comparison with AG/SAG Milling ... Table 3 A summary of RoM ball and SAG mill test conditions. Test AG T1 AG T2 RoM ball T3 ... Ball size, mm 80 80 Mill power, MW 4 ...

WhatsApp)

WhatsApp)

RoM Ball mills – a comparison with AG/SAG Milling ... Table 3 A summary of RoM ball and SAG mill test conditions. Test AG T1 AG T2 RoM ball T3 ... Ball size, mm 80 80 Mill power, MW 4 ...

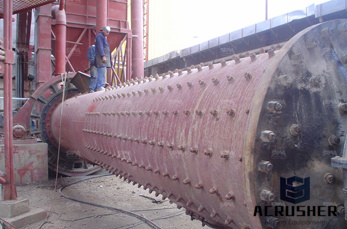

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

The 24'' x '' Ball Mill The Copper Mountain ball mills are 7315 mm [24 feet] in diameter and 12040 mm [ feet] long. They are overflow discharge ball mills with inside diameters of 7315 mm [24 feet] and grinding lengths of 11887 mm [39 feet]. Each Ball mill is .

The analysis of the influence of ball sizes in SAG grinding hasn''t been developed in detail by considering the effect on process parameters inside the mill, grinding efficiency or internal classification. Historically a conventional grinding reference has been made on the empirical .

Commercial ball sizes 10 – 150 mm; Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge. For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed,,

Most mills used in mining rely on impact to breakdown rock to a suitable size for downstream processing. The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grind...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS ... Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 ... 1700 microns coal using mm balls 83 Results of size analysis for + 26500 ...

May 08, 2015· Before making a change in the SAG mill ball size it is important to test it first in simulation. Before making a change in the SAG mill ball size it is important to test it first in simulation.

The selection of SAG and ball milling sizes and confi gurations for new projects is complicated by ... SAG pinion energy in kWh/t to grind from F80 152 mm to T80 mm, Bond Ball Mill Work Index in kWh/t, and the ratio of SAG kWh/t to BWi. The development of SAGDesign testing results in previous papers (Starkey, J. and s, M., ...

BATU HIJAU MILL THROUGHPUT OPTIMIZATION: MILLING CIRCUIT CONFIGURATION STRATEGY BASED ON ORE CHARACTERIZATION *F. Wirfiyata, and A. Maclean, G. Khomaeni ... feed size down to 2 mm 10 mm of product size with given maximum ball charge of 13% by volumea ... SAG mill and ball mill circuits have spare capacity. During these periods the throughput ...

The SAG mill product is then crushed to passing mm and is subjected to the Bond ball mill work index (S dBWI) grindability test to provide the total pinion energy at the specified grind size for mill design purposes, herein reffered to as micro ore hardness. The full SAGDesign test produces the SAG grindability (W SDT) and the Ball Mill

ness of the models. For a given mill to have a combination of feed size, ball load, mill speed and % solids will represent the total load. Ball Mill SAG Mill Scw Jb Pc % 6" +1" N/Nc Fresh Feed Water Water Pebble Crusher Screen Cyclones Sump Pump Fig. 1. SABC A/B milling circuit.

Equipment Specification Sheet: SAG Mill Specific Gravity tonnes/m3 Ball Mill Work Index metric P 80 88 µm Primary Grind P 80 43 µm Production Rate tonnes/hour Rod Mill Work Index metric Ball Mill Work Index metric Feed to SAG Mill 80% passing 150 mm Product from SAG Mill 80% passing 1000 µm SAG Mill Pinion Power 1155 kW

SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY ... (ball mill, rod mill, and MacPherson autogenous) and pilot plant ... Size K 80 (mm) 1 10 100 1,000. Although HPGR is a more recent

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ 5ROOLQJ ZLWK QLSSLQJ ... Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery ... LG A mill power equation for SAG mills. Minerals and Metallurgical Processing. Feb 1990 pp5762.

size distributions in AG/SAG mills. The existing models and understanding of grate ... The results indicate that mm is approximately the size below which particles experience no classification ( if presented to the aperture they will pass through). ... FIGURE 5 MILL OPERATING AS A PRIMARY ROM BALL MILL (TOP) AND AG MILL (BOTTOM). THE ...

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod millball circuit. All of the above contributes to

offers AG mills, SAG mills, ball and pebble mills, and stirred mills to your needs. By continuing to use the site, you agree to the use of cookies. You can find out more by reading our cookie policy. By continuing to use the site, you agree to the use of cookies. You can find out more by .

with a DEM simulation for balls (25 mm top size) in a laboratory ball mill (250 mm) is shown in the snapshot given in Figure 2. The postprocessing of these simulations allows slurry profiles and flow to be established in the mill as well as calculation of changes in impact and shear forces and energy dissipation with slurry rheology.

SAG mill itself and not on the test work program. Stated another way, money invested in a large SAG mill is an investment that can produce handsome returns if extra production is needed or simply to give the mine the option to mill the hardest ores at design throughput rates.

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit. A diagram of types of AG/SAG ...

SAG mills, Morrell (1993). The mill with scats had a considerably finer size distribution, and notably lacks ball in the 40mm to 60mm size range. This is the size at which the porosity is exposed, and they suddenly become smaller and nonspherical. For a normal finer ball size distribution a finer grind and lower throughput would be expected.

is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations. Grinding circuit design tools, including for SAG millball mill circuits, and geometallurgy energy models are available to subscribers.

WhatsApp)

WhatsApp)