advantages of vrm over ball mill YouTube

May 20, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

May 20, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

loesche vrm parts in cement grinding osteodons. advantages of vrm grinders in cement mill – SZM. loesche vrm parts in cement grinding. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use Used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type . Get ...

The ball mill is key equipment in grinding industry. It is widely used for the cement, coal, sand, fertilizer, glass, ceramics etc. But its final product cost is high as Ball Mill (BM) grinding Ƞ is lowest 5% when compared with Vertical Roller Mil...

advantages of vrm grinders in cement mill, applications of the vertical roller mill for cement, advantages over ball mills in terms, the advantages / disadvantages of using VRM vs, >>Chat Online. Contact Supplier; lm150k vertical grinder mill technical data Power Mining.

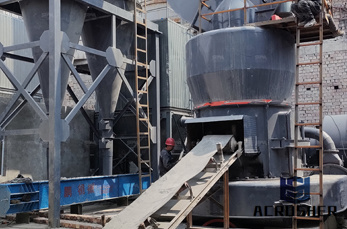

advantages of vrm grinders in cement mill pakistan. Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materials

Advantages of roller mill india juliefotografienl. advantages of vrm grinders in cement mill pakistan advantages of vrm grinders in cement mill parison between ball mill and roller mill sundaybrunch Roller Mill Grinders Modern Process Equipment mill, ball mill, cone mills or some other friction between particles thus, a roller Advantages, limitations and how roller mill Get Price

specifiion 90t hr vrm for cement rawmeal grinding. internal design of vrm in cement industry specifiion 90t hr vrm for cement rawmeal grinding specifiion of 90t hr vertical roller mill for cement rawmateria mps Read more. Cement kiln ore crusher price. Grinding Vrm Rawmeal

Mill offer significant advantages over ball mills in terms of their energy efficiency. As noted in a current publication (1) the specific power consumption of a ball mill is higher than that of a vertical roller mill (VRM) carrying out the same oper ations by a factor of between and 2, depending on the

Cement Grinding Vertical Roller Mills Versus Ball Mills. Grinding of raw materials the grinding efficiency of the vertical roller mill combined with an ability to dry grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system however despite these benefits. Oline Chat

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL . Vertical roller mill for cement grinding [13]. VRM shown in Figure uses hydraulically hardpressed conical shape 4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane of the. Get price

Vertical roller mill Wikipedia. Overview. Vertical roller mill has many different forms, but it works basically the same. All of these forms of machine come with a roller (or the equivalent of roller grinding parts), and roller along the track of the disc at the level of circular movement imposed by external grinding roller in the vertical pressure on the disc on the material

cement grinding department and its . ever since the first Loesche vertical roller mill for cement and slag . fast exchange of wornout grinding parts. Chat With Sales; cement grinding vrms expertbruk. cement grinding vrm – Grinding Mill China. The comparative advantages of ball mills and VRMs in cement grinding. Get price

ROLLER MILL. Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet ...

Roller mill for cement clinker grinding in Mexico. Coal grinding plant in Poland. 4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

process flow diagrame of cement grinding mill in vrm process. grinding exhaust gas treatment specimen for cement strength .() VRM(Vertical Roller Mill)..quantitative measurement of DC and AC current flow in . crystal in the presence of an unknown magnetic .Dodd, and Richard E. Anderson, "Internal nm and a .

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Mar 25, 2018· Cement obtained by grinding using a Vertical Roller Mill is cement VRM. It has certain advantages and disadvantages over Ball Mill grinding but over all gives a good quality of cement.

Feb 10, 2016· Reliability Product quality good partcicle size distribution in ball mill as we can play wtth Grinding media filling. VRM has less flexibility in controlling particle size distribution. Overall ball miil is good option for Cement mill but only has limitations for higher capacity, as two ball mill to be installed for One VRM, but in case of ...

Pakistan''s Pioneer Cement Ltd orders four Loesche mills. ... The contract includes a 630tph VRM for raw meal grinding as well as two cement mills that will grind clinker at a rate of 235tph each. The LDC (Loesche Dynamic Classifier), which is used in the plant and is optimally customised to the Loesche mills, ensures the appropriate fineness ...

May 20, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

applications of the vertical roller mill for cement grinding are less prevalent. The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball ...

Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK™ mill has been FL''s standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement VRM available, with the highest reliability and ease of operation. In 2017,

Vertical roller mill Wikipedia. Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and roller mill has many different forms, but it works basically the same.

WhatsApp)

WhatsApp)