Mining Official Wynncraft Wiki

Granite is the resource available to players with Mining level 10 or higher, and has a weight of 1. Refined Granite [ edit | edit source ] Refined granite is used to create .

WhatsApp)

WhatsApp)

Granite is the resource available to players with Mining level 10 or higher, and has a weight of 1. Refined Granite [ edit | edit source ] Refined granite is used to create .

Granite became "an integral part of the Roman language of monumental architecture". The quarrying ceased around the third century AD. Beginning in Late Antiquity the granite was reused, which since at least the early 16th century became known as spoliation. Through the process of casehardening, granite becomes

Dec 07, 2011· Prior to being installed in your kitchen, your granite takes quite a journey. Watch this video to find out where it comes from, how it is extracted from the earth, transported, cut and polished.

The recovery of marketable grade granite is reported to be 32 to 40 per cent in Karnataka, 25 to 75 per cent in four quarries around Jalore, the main granite mining centre of Rajasthan, and 20 to 40 per cent in Tamil Nadu. Granite exports from India last fiscal were worth Rs 3,018 crore.

granite mining process | Mining World Quarry. Mining method is the artificial granite mining, the traditional way of many mines are still ... Dartmoor tinmining Wikipedia, the free encyclopedia . .

Granite Mining Years of Plunder condoned by DME Environment ... May 22, 2010 ... In response to environmentally damaging granite mining, the Brits ... impact increases the cracking and breaking up of the granite rubble.

This huge model depicts the process of mining for granite and includes trains, cars, and boats that move around to convey the mining process. Read More.

The granite mining process involves two important stages of operation One is actual block splitting either from sheet rock or boulder and the other operation involves many items of works, such as removal of weathered zone or overburden, opening of faces, lifting of cut blocks, transportation and many other ancillary work before and after the ...

Mining Process | MidWest Tile. Mining Process The conversion of natural stone (marble, granite, slate, etc.) from the quarried mineral to the decorative home accent is a timely process. Blocks are cut from the natural quarries and transported to factories for cuts into slabs and tiles.

The process starts with a review of the layout in order to find the best way to break the quarry and easily mine granite from it. Moreover, a team of geologists and mining experts deploy several reports that define the condition of the ore mine before digging it deeper.

Mining Process. The conversion of natural stone (marble, granite, slate, etc.) from the quarried mineral to the decorative home accent is a timely process. Blocks are cut from the natural quarries and transported to factories for cuts into slabs and tiles. Midwest Tile, Marble Granite Inc''s product lines originate from quarries in countries ...

MINING. All the natural occurring stones like granite are mined from quaries and the process is called as quarrying. Learn More. DRESSING. The process of designing the granite according to the desired shape is termed as granite dressing. Learn More. SAWING. As per ancient archeologists, the best way to cut granite rock is sawing and the most ...

Kolkata diagram of mining in a quarry Henan Mining, stone grinder machine diagram wildpeppersf alluvial plant process flow diagram YouTube stone grinder machine diagram,25 Jun 2015, grinding machine for cement sands used stationary small rock crusher used small scale stone crusher australia second hand stone quarry parts in uk suppliers gold mining equipment china machines needed to .

Aug 18, 2018· As soon as the weight is lifted from the top by this mining process, the pressure from below cracks the remaining granite, which renders it nonmineable. >> Mining hillocks is more profitable, as the nonexportable granite (now regarded as rubble) is .

impact of granite mining on environment. Assessment of environmental impacts by mining ... Granite area mining projects draft environmental impact statement Key issues include the effects continued mining would have on the water quality of ... The chemicals used in the mining process often escape into the environment causing ...

Aug 20, 2016· After granite has first been mined out of the earth, it will be in a very rough form. After the mining process is complete, the granite will be sent to a workshop to be transformed into slabs. A technician will use milling machines to cut and polish the granite. Once milling has been completed, the slab will be between 7 and 9 feet long.

Granite is mined as either crushed stone or dimension stone mainly using open pit mining methods. Crushed granite represents 16% of the total crushed stone produced in the, and it is the secondmost utilized crushed stone in the Crushed limestone is by far the most commonly used crushed rock in the, representing 70% of total ...

Apr 24, 2017· Granite usually occurs in large deposits, many times referred to as slabs, throughout the world. Mining operations use different methods of cutting to extract the different deposits from the ground in places called quarries. These slabs are then polished, put on trucks and sent to fabricators.

offers 7,070 granite processing products. About 1% of these are machining, 1% are other food processing machinery, and 1% are other machine tool equipment. A wide variety of granite processing options are available to you, such as free samples, paid samples.

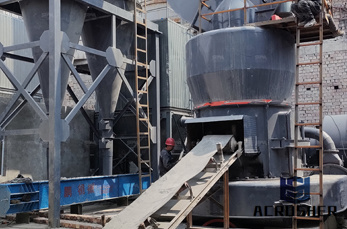

Granite Processing | From granite mine to your kitchen Granite mining is a large industrial process which begins with exposing a granite deposit. Once the granite deposit is exposed open cast mining .

Apr 25, 2018· SpreadON Studio : This Documentary is purely a voluntary effort, the documentary attempts to create public awareness about Granite Production Process Subscribe and press the bell icon for the ...

The remainder of the time is spent getting the granite slabs to market. The process of mining the rock and bringing it to market is complex. Luckily, MF Granite has an interesting video that shows the entire process within approximately 6 minutes. The video is eyeopening and down to business.

Granite Dimensional Stone Quarrying and Processing. Process flow diagram for granite quarrying operations As shown in Figure 1 the first step in quarrying is to gain access to the granite deposit This is achieved by removing the layer of earth vegetation and rock unsuitable for productcollectively referred to .

Aug 19, 2018· Granite that fractures during the mining process is discarded, because sellers require large slabs of the stone. Linda Mujuru, GPJ Zimbabwe The money the council receives is far less than what it got prior to 1996, when black granite''s status was changed by the Zimbabwean government from a natural stone to a mineral, Sigauke says.

WhatsApp)

WhatsApp)