The Nile Co., Ltd.

Ball Mill . Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs.

WhatsApp)

WhatsApp)

Ball Mill . Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs.

mining company, M, and a mill liner manufacturing company, L. The study focuses on a particular a grinding mill. A detailed description of the grinding mill is given in section The present study is a part of a research project whose goal is to find a costeffective maintenance decision system for mills in ore dressing plants.

Dewatering is an important process in mineral processing. The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density. This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue.

milling. The prior option is chosen when run of mine milling is not suitable and a coarse ... c. Ore dressing studies 3. Factors that influence the selection of crushing circuits ... Wet fine screening b. Factors effecting wet screening c. Types of wet screens d. Dry fine screens

The wet pan mill is named by the diameter of roller. 1300, 1350, 1400, 1500,1600 is suitable for selection of iron ore, molybdenum ore,lead ore,zinc ore, antimony ore and so on. 850, 900, 1000, 1100, 1200 is suitable for selection of gold ore.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Ball mill is a key device to crush materials after being broken. It is widely used in cement, silicate products, new building materials, refractory, fertilizer, nonferrous metal ore dressing production industries such as ceramics and glass, on a variety of ores and other materials for grinding dry or wet .

Many problems on free milling gold ores have been solved by the 911MPE Testing Laboratory. One free milling gold ore received for testing the application of the Mineral Jig in the Ball Mill Classifier circuit gave the following results: Head Ore, oz. Gold per ton (Assayed) oz. Gold per ton (Calculated)

YK series Vibrating Screen is the high efficiency screen that manufacture with German technology. It is suitable for screening stones in quarry, and also applicable for Coal dressing, Ore concentration, Construction, Electricity etc.

Ore Beneficiation. Ball Mill Rod Mill ... How to choose a right ball milling method for your material? of wet milling method and dry milling is the key to choose the right ball milling in the process of selecting a grinding ball mill is more economical and practical than dry ball mill ...

Either the End or Center Peripheral discharge rod mill can be used for wet or dry grinding. Whatever the type, the rod mill is used to produce a coarse product, whereas the ball mill is used to produce a finer product. Should a ball mill grind be required, the relationship of the length to the diameter of the mill is .

Appendix 1: Advantages and Disadvantages of Timber Frame Construction Table Advantages of Timber Frame Construction Potential Problems with Timber Frame ... studies of failures in regions with similarly wet climates and that were attributed to moisture intrusion and particular types of cladding. Appendices

The control of a milling operation is a problem in imponderables: from the moment that the ore drops into the mill scoop the process becomes continuous, and continuity ceases only when the products finally come to rest at the concentrate bins and on the tailing dams.

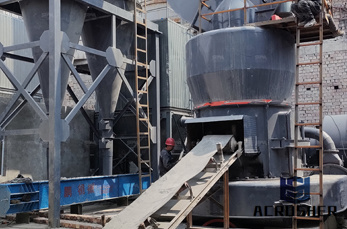

Huong Machinery is one of the biggest Crusher manufacturers in China, its main products are Roll Crusher, Hammer Crusher, Impact Crusher, Jaw Crusher, Stone Crusher, Cone Crusher, Stone Crushing Line, Sand Making Machine, Raymond Mill, Ball Mill, Dryer, Etc.

Milling is a type of machining during which rotary motion is always performed by a tool, and feed motion is performed by a tool or by a workpiece. The machines that are used for milling are called milling machines. The process of milling concerns ...

The particle size is of particular importance in this process. If the particles are too large, unwanted accessory minerals cannot be separated from the ore. The ore concentrate obtained only has a low purity. Overgrinding, on the other hand, results in high milling costs and low throughput as well as an increased need for chemicals in flotation.

Wet Grid Ball Mill . Capacity: Feed Size: ≤25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm.

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous is a high technological enterprise that integrated research ...

03 Wet milling with cutting fluid. There are some exceptions where cutting fluid should be used: 1)stainless steel and aluminum alloy fine processing used to prevent metal particles from sticking to the surface structure. 2)milling high temperature alloys at low cutting speed .

Advantages Dry Milling And Wet Milling. Advantages of dry milling dry milling and wet milling good price advantages and disadvantages of model 1200 wet, ball mill a ball mill is a type of grinder used to grind and out either wet or dry but the occur more. Read More; Goldore Dressing Wash Plant For Sale

Ball mill (also named grinding ball) is one of the most important grinding mills in the mining industry which is used to break all kinds of minerals and other materials in the industries of ore beneficiation, construction materials and chemical engineering. There are two grinding modes: wet type and dry type.

Welcome to Dajia Company, the product of choice for your mineral processing applications. We specialize in designing, developing, and manufacturing various lines of ore dressing and cement production equipment.

The ball grinding mill is with stable and reliable working condition. Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice. Ball mill for copper ore processing in India

GRAVITY SEPARATION IN ORE DRESSING. ... The most notable advantages of the gravitational methods are their cost effectiveness and in some cases excellent reduction. ... The wet .

WhatsApp)

WhatsApp)