Start Up Sequence of a Loesche Coal Mill YouTube

Dec 27, 2018· Start Up Sequence of a Loesche Coal Mill Duration: 8:12. LoescheGroup 24,373 views. 8:12. How Vertical Grinding Mills Work (Coal Pulverizer Example) Duration: 14:39.

WhatsApp)

WhatsApp)

Dec 27, 2018· Start Up Sequence of a Loesche Coal Mill Duration: 8:12. LoescheGroup 24,373 views. 8:12. How Vertical Grinding Mills Work (Coal Pulverizer Example) Duration: 14:39.

Jun 03, 2014· Vertical milling machine obviously does not exist the problem above, relative to the small and mediumsized customers in the European version of flour mill pulverized coal processing, the strength of the larger customers directly select the vertical mill (at present domestic and international largescale thermal power plants, cement plants have ...

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

Roller Mils are directly driven bevelwheel planetary gears or bevel cylindrical gear units. The gear unit represents an almost integral component of the mill. The output flange of the gear unit is rigidly connected with the grinding table. In addition to transmitting the torque,the gear unit also has capability to take up the reaction forces from the the griding force of the mils rollers.

Pulverized coal mills with throats that are too wide will have corresponding low throat velocity in the mill grinding zone that contributes to excessive coal rejects and fires. This is an example ...

Starting coal grinding mill is really easy if you are aware of the basics of coal grinding. Use a comprehensive business plan to get funding from potential lenders. If you want to start a coal grinding mill, you have to begin with the creation of a comprehensive business plan. You can use this to apply for a business loan or as a guide from ...

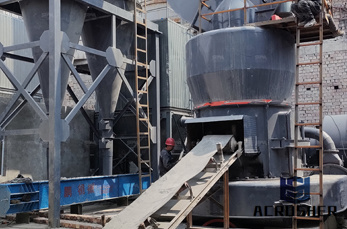

Vertical Coal Mill China Pengfei Group . This vertical coal mill is typically designed to process materials in medium hardness, like soft coal or bituminous coal, and it is mainly used in positive pressure pulverizing system of soft coal. It is widely used in electricity field, metallurgy sector, building material industry, chemical ...

Nov 22, 2012· vertical coal mill startup – MPS Mills Mill Parts – Welcome to There is no other vertical spindle coal pulverizer with more installed combined . mill vibration and impact load . »More detailed

Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mine

Vertical Roller Mills This mill uses hydraulically loaded vertical rollers resembling large tires to pulverize raw coal fed down onto a rotating table. As the ... coal pulverizer designs are Vertical Roller Mills. Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer.

18 inch Raymond Vertical Mill Raymond 10500 20 35 inch Raymond Vertical Mill Raymond 200 VERTICAL MILLS IMP MILLS The imp mill is extensively used for processing and pulverizing of many materials. Typical grinding applications include CLAY, GYPSUM, KAOLIN, TALC, PIGMENTS, STARCHES, LIME PRODUCTS, OXIDES, INSECTICIDES LITHARGE.

These arguments also convinced Helwan Cement Company belonging to the Italcementi vertical roller mill chosen by Helwan Cement Company will be installed in a coal grinding plant of a cement works in Egypt. The delivery of the coal mill will start as early as the end of order was placed by the Chinese General Contractor ...

Mar 03, 2014· Principle of operation bowl mill 1. Principle of Operation Bowl Mill is driven by AC motor, coupled with flexible coupling to the worm shaft. The worm shaft drives worm gear, mounted on the Main Vertical Shaft. A bowl mounted on the top of the shaft rotates at a speed of 40 to 65 rpm.

Inerting System Design for Medium Speed Vertical Spindle Coal Pulverizers The PRB Coal Users'' Group plans to develop a Design Guide for Mill Inerting as an aid to users when designing a mill inerting system. This is a first draft document by the The Group on the subject of mill inerting. Feedback is encouraged. TABLE OF CONTENTS Preface 2

2. After grinding system has started, please turn on the rod valve in the bottom of raw coal storage, and start sealing measuring belt to coal mill, then raw coal will be dryed and ground in the vertical coal mill. 3. The mixture of hot air or waste gas of cement production line are sucked into Vertical Coal Mill, under blower''s function ...

GRMC coal vertical roller mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China. It is the first choice equipment for grinding raw coal and bituminous coal. 1. The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through ...

May 14, 2006· In such cases, subsequent mill startups will run at leaner air/coal ratios and higher air velocities, increasing the probability of mill puffs and explosions. Unless accurate and updated ...

Apr 29, 2014· Start Up Sequence of a Loesche Coal Mill 1,473 views. Share; Like... LOESCHE. Follow Published ... Hydraulic system vertical roller mill operation linxiaomo. Get Fit For The Future Dry Ore Comminution Technology LOESCHE. Truck Unloading Station LOESCHE. PlanEX Discharge System ...

Loesche in Düsseldorf received a followup contract for a coal mill, of the type LM D, which is the same type of coal mill already successfully deployed by RWE Power AG in Niederaußem. In July 2012, RWE Power in Essen commissioned a new vertical roller mill from Loesche (Fig.).

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

The LM vertical grinding mill has become the best choice for pulverized coal production. It also improves the safety and environmental protection of the production process while ensuring the quality and production efficiency. It is the best performance and most comprehensive equipment of pulverized coal mills.

Pulverizers Coal Grinding Roller Mills William''s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

The vertical spindle mill crushes coal by feeding it between a grinding roller and either a bowl, table or ring at the bottom. ... To ensure that at mill start up and low load (throughput) operation, there is sufficient air flow to maintain the minimum required velocity to prevent particle settling in the PF pipes.

Vertical Spindle Mills The vertical spindle mill is a medium speed pulverizer and maintains a considerable amount of fuel in the mill system when operating. Coal collects on the grinding table, in the classifier, in the pyrite collection sec tion below the grinding table, .

WhatsApp)

WhatsApp)