Portable Concrete Mixer Batch Plant | Right Manufacturing ...

EZ 152 Portable Concrete Mixer and Batch Plant. The EZ 152 portable concrete mixer and concrete batch plant mixes just over cubic yards ( cu ft) of concrete.

WhatsApp)

WhatsApp)

EZ 152 Portable Concrete Mixer and Batch Plant. The EZ 152 portable concrete mixer and concrete batch plant mixes just over cubic yards ( cu ft) of concrete.

Precast concrete plant equipment products are most popular in Southeast Asia, Africa, and Domestic Market. You can ensure product safety by selecting from certified suppliers, including 442 with ISO9001, 79 with Other, and 34 with ISO14001 certification.

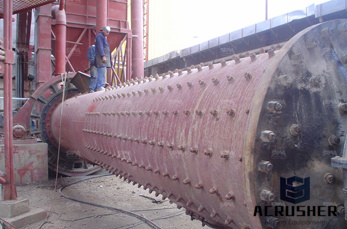

Great Wall is the professional manufacturer of cement machinery with the production experience for more than a half of century. Our company put forward a suit of highly effective solution for frequently asked questions in the process of cement production. This solution can effectively reduces power consumption and dust pollution of cement plant, reduces manual operation, as well as improves ...

Find Stationary Concrete Batching Plant,Precast Concrete Batching Plant and more construction machinery,Fujian Xinda Machinery Co.,Ltd. will be your ideal choice as we are the premier leader in concrete plant machines industry.

HOME major plant amp machinery required for cement plant. Cemco, Inc. | Cemco Model 275 Mobile Concrete Batch Plant. The entire plant is compact and has a small footprint when setup. The 275 batch plant pulls in one unit and is sold as a complete, operating batch plant. Everything needed to set up and batch concrete is standard equipment on ...

Hello, I am interested in starting up a manufacturing plant of cement concrete bricks at Lucknow, Uttar Pradesh . Please guide with the basic requirements to start up the business. 1) Money required for automatic and semi automatic manufacturing plant. 2) Land required for setup. 3) Tentative cost for both type of machineries.

Ready Mix Concrete Plant Inspection Checklist Addendum Procedure General Notes: • The following items are to be verified (if applicable) during the NRMCA plant inspection for concrete plants seeking NCDOT Certification. • If a plant is actively producing concrete for use on a .

Ready Mix Concrete Plant Inspection Checklist Addendum Procedure General Notes: • The following items are to be verified (if applicable) during the NRMCA plant inspection for concrete plants seeking NCDOT Certification. • If a plant is actively producing concrete for use on a .

Cement Plant Machinery. OVERVIEW. ... control and automation of complete cement plant equipment and clinker grinding units on EP basis. ... reputed and proven technology providers overseas WIL offers you a single source solution for everything needed to set up a new modern, power and fuel efficient cement plant and clinker grinding units. ...

Tools, Equipment and Materials " DISCLAIMER: The ILO does not take responsibility for content presented on this web portal that is presented in any language other than English, which is the language used for the initial production and peerreview of original content.

How should cement plant machinery and equipment repair and maintenance . Date: 15:33 Source:cementepc Views: Equipment maintenance is built on the basis of repair, and other work, one of the main person in charge of the workers, is often in good condition to maintain the important means of equipment, is an active precaution ...

Jul 02, 2015· I am assuming you intend to establish a cement manufacturing mill/plant, and be a part of the larger industry. You don''t set up a Industry. On that note, starting a cement manufacturing business requires serious time, energy, and capital investmen...

Concrete Batch Plants for Sale: Ready Mix, Precast Central Mix. F Direct is a fullservice dealer for all sizes and types of concrete batch plants, both new .

0511 Dock Barge with Cement Batching Plant 0512 Lifting Assembling Barge CONCRETING EQUIPMENT: 0601 Batching Plants 0602 Mixers 0603 Concrete Pumps 0604 Transit Mixers 0605 Dumpers 0606 Concrete Placers QUARRY EQUIPMENT: 0701 Crushers 0702 Screening Plants 0703 Pneumatic PNEUMATIC EQUIPMENT: 0801 Rock Drills 0802 Compressors 0803 Pavement ...

Manufacturers of Cement Plants, Cement Plant Project, Cement Plant Equipment, Rotary Kiln Cement Plants, Industrial Cement Plants, Cement Manufacturing Plant, Large Cement Plant, Mini Cement Plant, Clinker Grinding Units, Grinding Mills, Ashoka Machine Tools Corporation.

Equipment used at a concrete batching plant includes silos, weigh hoppers (batchers), conveyors, mixer engines and auxiliary generators. Concrete batching plants are eligible to operate in Florida under the terms of an air general permit (AGP) pursuant to the requirements of Rule (5)(b), Florida Administrative Code ().

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Ashoka''s cement plant unit has continued focused on objectives of product improvement and quality. In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards.

Aug 20, 2019· Since concrete waits for no one, the right tools can make the difference between a successful pour and a potential disaster. Most of the essential tools are basic and do not require a significant investment. Owning these eliminates the cost of rental fees and the lost time picking up and returning the equipment. Some specialty equipment is more ...

If there is a need for a new plant, a thorough process leads to a successful outcome. "Our team often starts with factory layout plans, moving on to the factory details, specific solutions and machinery. This is what we did with the Karkas Monolit factory in Russia. It was a good example of a wellexecuted process," Raukola notes.

Leading manufacturer and supplier of quality Stationary Concrete Batching Plant by Atlas Equipments. Quality machines at reasonable cost. Source your concrete mix plant from us. Rugged structure, advanced design, simple to use control panel make this equipment the choice of many leading civil contractors worldwide.

The entire plant is compact and has a small footprint when setup. The 275 batch plant pulls in one unit and is sold as a complete, operating batch plant. Everything needed to set up and batch concrete is standard equipment on every Cemco Model 275. CEMCO technicians operate and inspect the plant thoroughly before it is shipped to the customer.

Commissioning and startup is the final step before production runs in a processing plant. As part of our larger product lifecycle solutions, AMG, Inc. is uniquely poised to perform commissioning and startup and the accompanying troubleshooting and problem solving activities as part of a design/build project.

Batching Of Concrete Method Statement for construction project. Download the method statement template and use it in monitoring Batching Of Concrete. ... The scope of this procedure covers checks required to be carried out prior to and during the site batching of concrete. PROJECT: PROJECT NAME. ... Calibration record of all equipment of ...

WhatsApp)

WhatsApp)