Wear mechanism of coated and uncoated ... Cambridge Core

Wear mechanism of coated and uncoated carbide cutting tool in machining process Volume 31 Issue 13 Jar A. Ghani, Che Hassan Che Haron, Mohd Shir Kasim, Mohd .

WhatsApp)

WhatsApp)

Wear mechanism of coated and uncoated carbide cutting tool in machining process Volume 31 Issue 13 Jar A. Ghani, Che Hassan Che Haron, Mohd Shir Kasim, Mohd .

Synthesis of nanomaterials by a simple, low cost and in high yield has been a great challenge since the very early development of nanoscience. Various bottom and top down approaches have been developed so far, for the commercial production of nanomaterials. Among all top down approaches, high energy ball milling, has been widely exploited for the synthesis of various nanomaterials, nanograins ...

Magnesium gradually goes into solid solution during ball milling and after 3 h almost all of the Mg atoms are soluted into the Al matrix. With increasing milling time the Mg content in solid solution, the dislocation density as well as the hardness are increasing, whereas the crystallite size is decreasing.

Jan 10, 2020· Hierarchical Ndoped porous carbons (NPCs) with large surface area and controllable Ndoping are synthesized by ball milling, followed by pyrolysis. As a .

S6 Fig. S3 HPLC chromatograms of (a) the astaxanthin standard purchased from SigmaAldrich dissolved in DMSO at a concentration of 1000 ppm, (b) Soxhletextracted sample in acetone of untreated H. pluvialis at 65 C for 24 h; HPLC chromatograms of onepot, simultaneous cell wall disruption and extraction in ethanol at 200 rpm and feedtosolvent ratio of 1:10

D. Sumanth Kumar, ... Mesh, in Synthesis of Inorganic Nanomaterials, 2018. Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell.

Can magnesium granular powder be ball milled to fine powder? ... Of Course, Definitely you can use ball milling for mg alloys but may i know the composition of mg in that alloy. Because in mg ...

Effect of ball milling process on the structure of local clay and its adsorption performance for Ni(II) removal. ... (mg/g), and q m and K L are Langmuir constant. ... properties of the purified clay was observed after 5 to 20 h of ball milling at 500 rpm, with 10:1 or 20:1 of weight ratio of balls to powder. ...

Li 2B 10H and Na B H were synthesized from decaborane (B 10H 14, Katchem), dimethyl sulfide, liquid ammonia and the respective hydroxidesMOH, using amethoddescribedelsewhere. 41 Li 2B 12H 12 4H 2OandNaB H xH 2O (Katchem) were heated to 245 1C under dynamic vacuum for 12 hours to remove coordinated water. The closoborates M 2B 10H or M B 12H ...

Widatall We present results on the thermal dependence of the magnetization above ambient conditions of ZnFe2O4 nanoferrites having different degrees of inversion (c∼–) and grain ...

The authors obtained magnets with 𝐵 𝑟 of T, 𝐻 c i of kA/m and (B H) m a x of kJ/m 3. They also reported that a high ballmilling pretreatment was helpful for obtaining magnets with fine grains and even microstructure with an increase of the 𝐵 𝑟 and (B H) m a x to T and kJ/m 3, respectively.

Jan 21, 2020· An efficient method of mechanochemistry for the synthesis of N‐methyl‐C‐(2‐furyl) nitrone and intermolecular 1,3‐dipolar cycloaddition reactions with activated alkenes and electron deficient alkynes have been studied by employing ball‐milling technique.

Synthesis of MgCuTi based amorphous alloys by mechanical alloying technique C J Hu, H M Wu and T Y Chen Department of Materials Engineering, Tatung University, Taipei, 104, Taiwan E .

Apr 20, 2011· Microalgae as Sources of Carotenoids. ... —from which mg L −1 of βcarotene was recovered ; however, this figure could be improved up to mg m −3 d −1 in continuous biphasic ... provides full recovery, but it cannot be scaled up to industrial practice; sonication and ball milling produce results similar to that ...

In this paper, a summary of work performed in the area of modeling of the dynamic metal cutting process is presented. A general view of evolution of the dynamic cutting process models is depicted.

Nov 22, 2016· Again as I said it all depends on ball milling technique with type of mill used, ball to powder ratio and milling time. All these have huge impact on the CNT structure. View

The influence of ball milling and subsequent calcination of a 1:1 molar mixture of αFe 2 O 3 and Li 2 CO 3 on the formation of LiFeO 2 has been investigated. Premilling was found to lower the temperature of ferrite formation by ca. 200°C and a thermally stable γLiFeO 2 phase was found to form

It was shown that ballmilling under hydrogen atmosphere is a convenient method for the formation of metal hydrides which causes simultaneous hydrogen uptake and mechanical deformation resulting from ballmilling. Huot et al. produced MgH 2 under H 2 atmosphere by ballmilling. This method improved the hydride formation kinetics.

Jan 31, 2011· Ma, J. Zhu, Wu, and Zhang, 2009. Application of backpropagation neural network technique to highenergy planetary ball milling process for synthesizing nanocomposite WC–MgO powders.

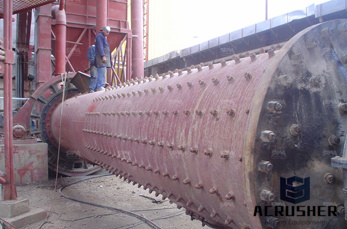

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Ball milling allows for solventfree mechanoredox catalysis "Unlike photoredox arylation and borylation reactions, mechanoredox catalysis reached high yields in much shorter times." trend is consistent with a div erngt ph s coherent length in the superconductor, a

To prepare homogeneous powder mixtures, Ti, Al, and TiC powders were first weighed to achieve Ti/Al/C = :: ratio and mixed them together using ballmilling with zirconia beads in a glass jar at the speed of 300 rpm for 24 hours (18, 28).

After the treatments, the sample was milled in a ball mill (Marconi MA500 – 200 rpm) with a variation of three different milling medium. The liquid milling medium were: i) dry medium (CNSD); ii) moist with water and (CNSW) iii) moist with ethanol (CNSE).

Microstructure of Mg 50Co 50 alloy prepared by ballmilling Figure 2 shows the pressure–composition (P–C) isotherm at room temperature of Mg 50Co 50 alloy prepared by ballmilling for 100 h. It should be noted that the maximum content of hydrogen was D/M (D/M: the ratio of the number of D atoms to metal atoms) and D/M of ...

WhatsApp)

WhatsApp)