Home []

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grindball. At the same time we can use different forms of the shell liners ...

WhatsApp)

WhatsApp)

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grindball. At the same time we can use different forms of the shell liners ...

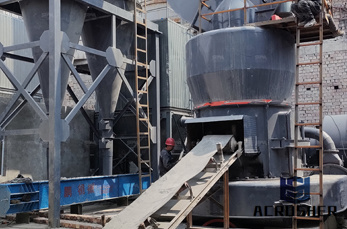

JYS CASTING Machinery Offers Ball Mill Spares Parts . Ball mill machines are widely used in the metal scrap crushing, mining crushing machinery, and chemical, cement and power generation plant machinery spare parts. JYS CASTING Ball Mill Liner. JYS CASTING provides customised ball mill liners. These parts are cast on a resin sand production line.

Ball mill liners from MGS Casting maximize the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners available. Refined through ongoing design improvements, our ball mill liners maximize uptime and service intervals while providing an improved crushing of the ore.

Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control. Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break particle based on impact and attrition.

Ball mill liners from Multotec maximise the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners available. Refined through ongoing design improvements, our ball mill liners maximise uptime and service intervals while providing an improved crushing of the ore.

Zirconia Ball Milling Rubber Liners For Ball Mills Ball Mill Rubber Lining, Find Complete Details about Zirconia Ball Milling Rubber Liners For Ball Mills Ball Mill Rubber Lining,Ball Mill Rubber Lining,Rubber Liners For Ball Mills,Zirconia Ball Milling from Mine Mill Supplier or ManufacturerHenan Bailing Machinery Co., Ltd.

Oct 29, 2015· Java Project Tutorial Make Login and Register Form Step by Step Using NetBeans And MySQL Database Duration: 3:43:32. 1BestCsharp blog 6,118,924 views

Mill liners. No matter what application you have or what type of mill liners you are looking for, has the solution for you. Our mill liners are the choice of customers in more than 100 countries, and over 4,000 mills worldwide are lined with liners.

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Ball Mill Joint Rubber Lining. This is a existing (china design ) ball mill rubber lining design which will be useful for easy maintenance,replacement of few pieces of .

Wuxi Orient Antiwear Engineering Co.,Ltd. is best Ball Mill Liners, Mill Liners and Cement Mill Liners supplier, we has good quality products service from China.

The centrepiece of RME''s mill relining system is a RUSSELL 7 or RUSSELL 8 (seven or eight axis) liner placement mill relining machine. Available in maximum liner capacities from 500kg to 7,500kg, these machines represent the ultimate in new liner replacement capability.

The speed of the mill, type of liners, grate openings for ball mills, size and type of feeder, size and type of bearings, trunnion openings, mill diameter and length, as well as many other smaller factors are all given careful consideration in designing the Ball Mill.

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

Rubber mill liners with superior designs that last longer. The yield of your grinding circuit is highly dependent on your mill''s liner. Select your mill liner partner carefully to make sure your mill is running at maximum capacity and availability.

Larger mills can be supplied with gear boxes, or direct synchronous motor drive, and variable speed can be an option. Ball Mill or Rod Mill Spares. We can supply liners from existing drawings and designs or as per request can design new liners to optimise wear life and improve grind.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls .

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected.

Ball mill liner One of the most common types of grinding machines used today in many industries is a ball mill. This device works by using mass media balls made of solid materials, embedded in a compartment or container, in such a way that the material is crushed and powdered at the time of the [.]

May 27, 2019· Onlin Service : This Channel Have Equipments Working Video : https:// mining ball mill bricks ...

Bradken is a leader in the design, manufacture and supply of mill and crusher liners for primary and secondary applications in the global mineral processing and quarrying industries. We offer our customers complete wear liner solutions for mills and crushers that increase performance, equipment availability and lower maintenance costs.

Classification liner for the second chamber of the ball mill | Industrial ... For the conventional mill using a liner with lifter, however, it was difficult to reduce the ball diameter drastically because the grinding efficiency is extremely...

Ball Mill|Specification of Ball Mill|Ball Mills for sale . Ball mill is important for the secondary ghe material entering the hollow axis by the feeder,the material will be taken evenly and spirally into the first warehouse,where there is the ladder liner or the ripple liner .

Protect your mill from mineral process abuses while ensuring optimum grinding and crushing efficiency with Multotec''s ball mill liners. Read More. SAG Mill Liners. Multotec SAG mill liners use specialised software and rubber composite components to provide superior impact and wear resistance.

WhatsApp)

WhatsApp)