(PDF) Optimizing the control system of cement milling ...

Optimizing the control system of cement milling: Process modeling and controller tuning based on loop shaping procedures and process simulations ... model of cement milling process .

WhatsApp)

WhatsApp)

Optimizing the control system of cement milling: Process modeling and controller tuning based on loop shaping procedures and process simulations ... model of cement milling process .

AGICO Cement Ball Mill Cement EPC Project. The closedcircuit grinding system is not suitable for any cement plant. On the one hand, its process is relatively complex and the number of equipment is large. On the other hand, it has strict requirements for related equipment and production management.

This research focuses on investigating the effects of the three different grinding aids, consisting of a mixture of amine, glycol and polyol in different ratios, on the model parameters of a twocompartment cement ball mill and an air classifier.

The process of cement production includes several stages and concludes by grinding clinker with the addition of gypsum. Grinding precision is an important characteristic of cement, since it defines the amount of material capable of hydration. The rate of hydration and strength increase also depends on this parameter.

The cement process simulator is an option to be integrated into SIMATIC PCS 7 CEMAT, enabling a realistic reconstruction of the behavior of a cement plant. The digital twin offers virtual commissioning, operator training and seeing the plant behavior by changing the process parameters before launching into real production.

potential ability of the process engineers to control processing parameters to accomplish the desired cement fineness levels. In the second part of the study, a quantitative procedure for monitoring and evaluating cement milling process performance was described. Some control charts

Type of grinding ball mill process nov 12 2018 ball millball millsball mill machines diffrent type process parameter in cement ball mill mining ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture,Cement Mill Process Parameter List.

Feb 10, 2016· gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare with the product of a ball mill relative to these parameters. Other parameters(VRM vs. Ball Mill) to be considered are the following:

Get Price cement mill process parameter list. Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more ...

Sep 17, 2015· Cement Production Process ... The output of a cement mill is the final product viz. Cement. The term bag house is applied to large filters containing a number of tubular bags mounted in a usually rectangular casing. The dust laden air is drawn through them by suction. ... It is the place from where all the process parameters are controlled. 16 ...

Temperature is a crucial process parameter in the manufacturing of cement. The correct monitoring of temperature at various stages of the process Kiln Motorbearing, Conditioning tower, Flue discharge, Preheater cyclones, Smokebox and fuel storage determine the quality of clinker and the final product.

Process Parameters Vertical Roller Mill Global. Process Parameters Vertical Roller Mill Vertical roller mill wear parts the vertical roller mill by the separator roll grinding grinding pressure device reducer motor shell etc the separator is an important component for ensuring product fineness it consists of the drive system rotor guide vanes a ...

Illustration of OK™ cement mill roller profile. Technical details about the OK™ cement mill Example of ROKSH separator for optimum cement product quality. Handle multiple materials with ease As the operating parameters can be adjusted instantly and the retention time of the system is very short, the switching between

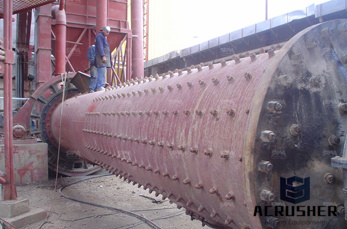

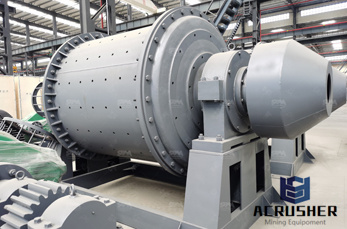

Cement mill is also called cement ball mill, which is mainly used for grinding cement clinker in the cement production process. It is one of the important cement equipment. The output of cement mill is 21~155 t/h, and the specific surface area of cement is 3300~3800 cm ² /g.

Mill Grinding Course PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course. Kiln Process Program

detailed description of the process principle, influencing parameters, process agricultural, and defense equipment, gears for large mills used for producing cement, Conventional processes namely gear grinding, gear shaving, gear .. designed using Taguchi''s experimental design technique (L9 .

cement mill process parameter list in india ThyssenKrupp Industrial Solutions In the cement industry, ball mills are the most commonly used machines for raw 47/5(747) cement mill process parameter list hotelkanya The cement industry of the 21st century is The challenge in identifying a cement ball mill process is The online B Process .

vertical roller cement mill process parameters. vertical roller cement mill process parameters. Coal Mill Sale>vertical roller cement mill process Comments. roller mill is the large grinding mill that is mainly used in coal grinding plant and cement g 3 rocess Simplification By changing various Know more.

vertical mill for separate grinding process in cement Cement Plant Mill (Grinding) scribd Chaeng vertical roller mill for cement, slag, coal and so,Nov 06, 2016,coal vertical millUsed Cement Plant,, Cement Production Line Cement Grinding Plant Industrial Kiln and Furnace Grinding Equipment Technical parameters of 1500X limestone super . Chat Now

been made to optimize PID controllers of cement milling. The process simulation is combined with an autoregressive model of the errors between the actual process values and the computed ones. Long term industrial data have been used to determine the model parameters. The data include grinding of various cement types.

In this work the relation between the change in mill output and cement fineness caused in the ball mill grinding process of composite cement with respect to different operating input parameters ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement mill is also called cement ball mill which is mainly used for grinding cement clinker in the cement production process it is one of the important cement equipment the output of cement mill is 21155 th and the specific surface area of cement is 3300,Parameters Of Cement Mill.

Iron Ore Processing Plants South Africa Beneficiation Production Line Pakistan Magnetic Separation Process Molybdenum Ore Beneficiation Line in Congo Magnetite Magnetic Separation Process in Zimbabwe 15T/H Iron Ore Beneficiation Line in Turkey 21T/H Ball Mill for Processing Silicate in Bangladesh 25T/H Magnetic Separator Used in Singapore ...

WhatsApp)

WhatsApp)