Gold Ore Processing Plant, Crushing Quartz Hardrock Gold ...

Jan 15, 2019· This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant. This system is specifically designed for the small to .

WhatsApp)

WhatsApp)

Jan 15, 2019· This is a video showcasing our 1 ton per hour complete, chemical free, gold ore gravity processing plant. This system is specifically designed for the small to .

Sep 23, 2017· The 10 tons per hour rock gold ore process plant in Zimbabwe Africa, the plant adopted machines such as jaw cruher, hammer crusher, ball mill, spiral classifier, jig machine, centrifugal gold ...

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

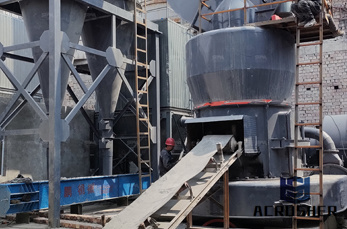

JXSC is a gold processing plant manufacturer, find qualified gold ore processing plant equipment in China, applied in alluvial gold, mineral process. Get the related gold mining equipment include stone crushers, mineral separator, shaking table, spiral classifier, etc. Check price.

If this ore also contains 1g/t Au (for GSR =1), and 90% recovery to concentrate is achieved, then will be recovered and with a concentration ratio of 20 (5% to concentrate) this corresponds to 18g/t Au in concentrate. At current gold prices this is worth about US600.

Read the latest chapters of Developments in Mineral Processing at, Elsevier''s leading platform of peerreviewed scholarly literature

Jun 19, 2015· I tis a good margin / margin protected business – buying ore at a discount to the spot gold price, processing through the plant, and selling the gold or goldincarbon at market.

Commissioning and Operating Experience with Gekko''s Gold Ore Treatment Plants 5 Figure 4: Bong Mieu Processing Plant Flowsheet (PostCrushing) The Gekko Resin Column The Bong Mieu plant is the first fullscale gold operation to use AuRIX®100 ionexchange resin and the Gekko Resin Column.

Assuming that a gold ore has been effectively ground to ensure maximum economic liberation of gold, the circuits that will have the most effect on the successful operation of a gold plant will be that of the leaching and carboninpulp circuit (CIP). The reagent and utilities operating costs associated with leaching, adsorption, elution and ...

It is a high technological enterprise that integrated research, manufacture, sales and service . The company has multiple subsidiaries such as Mineral Processing Research Institute...

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing completely updated edition features coverage of established, newly implemented ...

Gold Processing Plant | Gold Mining Equipment for Sale. JXSC is a gold processing plant manufacturer, find qualified gold ore processing plant equipment in China, applied in alluvial gold, mineral process. Get the related gold mining equipment include stone crushers, mineral separator, shaking table, spiral classifier, etc. Check price

Gold Ore Processing. Star Trace''s range of services covers all processes needed for the recovery of gold, from Ore to Dore bar and So on. Converting runofmine (ROM) ore into saleable Gold Silver products. Integrating engineering and process knowhow in development and optimization of plant designs using state of the art technology.

GOLD PROCESSING PLANTS. Portable placer gold processing plants for alluvial mining, screen deck classifying jigs for alluvial dredging and mining, self contained gold processing plant, fine gold recovery, gold processing plants, gold processing plant, mine plant, mining plant, mining plants, placer gold recovery plant, gold processing plants, GOLD, PROCESSING, PLANTS.

Gold ore processing plant includes different types of process namely: ... Smelting; Gold ore processing plants should be started with the feeder and it will take the extracted materials uniformly to the crusher for the first process. This process is used for resize and pulverize the gold ores into smaller than particles. For secondary crushing ...

available for the extraction of gold metal from its ores. Amongst these methods, cyanidation is the most common method used in the leaching of gold from the ore. This process involves the dissolution of gold containing ores in dilute cyanide solution in the presence of lime and oxygen. For refractory ores such as

Oct 25, 2011· Gold Ore Processing Plant, ... Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the process of taking...

Flotation process can maximum enrich gold to the sulfide mineral, tailings can be abandoned directly, the cost of processing plant is low, 80% of China''s rock gold are used in this method. Flotation process that mainly including dosing, mixing, filling, blowing etc . Details >

20+ items· 21 Gold Ores Processing Companies in the United States. Search or browse our list of Gold Ores Processing companies by category or location. ... Manta has 21 companies under Gold Ores Processing in the United States. ... Modular Gold Plants gold ores processing gold ores processing. Specialists in Advanced Gold Processing and Water Treatment ...

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

Used Mining Processing Equipment for Sale. ... 10,000 TPD Gold Plant w/SAG Ball Mills, Gyratory Cone Crushers, Rock Breakers More, ... Plant Iron Ore Processing 3000 tpd, Magnetic Separators, Westech and FL Vacuum Filters and Ametek Drum .

Plants for the production of lead are generally referred to as lead lead production begins with lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite, zinc, caustics or pollution control particulates. Smelting uses suitable reducing substances that will combine with those oxidizing elements to free the metal.

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding .

The technique using dissolution with alkaline cyanide has been highly developed over recent years. It is particularly appropriate for low grade gold and silver ore processing ( less than 5 ppm gold) but its use is not restricted to such ores.

WhatsApp)

WhatsApp)